-

Applications

-

About Bruynzeel

-

Highlights

We are climate neutral in our own operations

(SCOPE 1 & 2) AND COMMITTED TO REACH NET ZERO (SCOPE 3) BY LATEST 2045

We are proud to have achieved the milestone of being climate neutral in our own operations (scope 1 & 2) according The Greenhouse Gas Protocol (GHG) over the year 2021. We have been independently audited by Deloitte*.

We are currently working hard, together with all stakeholders, to also bring our Scope 3 emissions of the GHG protocol to zero by 2045 latest. To achieve this we work with yearly improvement targets. Well in advance of the Paris Climate agreement.

* Official Deloitte audit report (Bruynzeel Storage Systems Scope 1 Scope 2 Report 2021) available upon request.

We eliminate our emissions by solely procuring 100% electricity from local solar and wind installations (Certiq: www.certiq.nl) and gas from local bio digesting installations (Vertogas: www.vertogas.nl)

How can we help our customers and partners?

Footprint

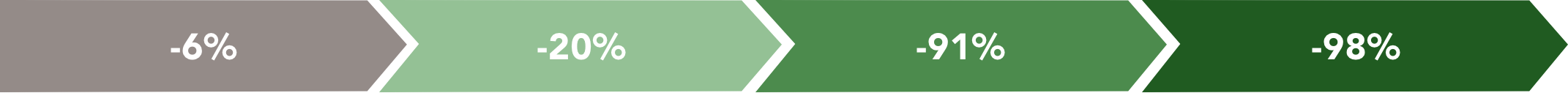

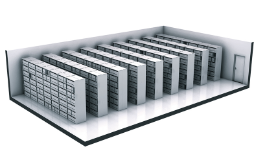

Traditionally, storage is kept in static equipment alongside aisles. These aisles are needed to access any of the items in storage. In practise, the majority of this aisle spaceis empty at any given time. A waste of space! The concept of space creating storage solutions is based on the principle of a “flexible aisle”. By making the storage equipment movable, an aisle can be created where needed, using the remaining space purely for storage. When applying our DoubleDecker solution, we literally take this principle to the next level by adding a second tier to the solution.

By applying Bruynzeel’s space saving storage solutions, our customers achieve immediate physical footprint reduction up to 75% and additional utility (lighting, heating, cooling, cleaning) and unnecessary building materials savings.

Traditional storage

> 50% of space not used for storage

> 50% of space not used for storage

Mobile storage

Save 50% m2 space

Save 50% m2 space

Double Decker mobile storage

Save 75% m2 space

Save 75% m2 space

In need for more space?

Optimizing existing floor space can reduce environmental impact by up to 90% versus new build!!

In case you need more space for students, increase stock levels in retail or find storage space for growing collections, regularly building extensions or complete new buildings are considered. Regularly the opportunity of optimizing existing floor space by over 50% is overlooked to solve these needs for additional space. Beside savings on investments, lead times for permits and building materials and required labor capacity, the CO2 impact that can be reduced over 20 years is significant….up to 90%!

A 20 years CO2 impact comparison PER m2

New-build

Initial impact

CO2 impact new construction per m2

source

400 kg CO2

Static storage solution per m2

source

107 kg CO2

Total *

507 kg CO2

Running impact

Energy (heating/cooling) per m2 p/year

source

107 kg CO2

#Years

20

Total (over 20 Years) *

2,140 kg CO2

Total impact

2,647 kg CO2

Optimizing existing floor space 50%

Initial impact

Bruynzeel mobile storage solution per m2.

source

309 kg CO2

Total *

309 kg CO2

Running impact

No additional m2 to Heat/Cool

0 kg CO2

Total impact

309 kg CO2

KG CO2 reduction optimizing existing space vs new-build

2,338 kg CO2

* Please note these figures represent an average indication. Exact figures may vary per country and project.

Embodied Carbon Benchmark Study

https://carbonleadershipforum.org/wp-content/uploads/2017/02/CLF-Embodied-Carbon-Benchmark-Study.pdf

closeStatic storage solution per M2 (50% aisle, 50% cabinet) = Avg 45 Kg Steel p/sqm (Bruynzeel estimate)

1 KG of Bruynzeel Standard (unoiled non-galvanized) steel emits 2.38 KG CO2. Source

45*2.38 = 107 Kg CO2

closeBruynzeel mobile storage solution per M2 = Avg 130 Kg Steel p/sqm (Bruynzeel estimate)

1 KG of Bruynzeel Standard (unoiled non-galvanized) steel emits 2.38 KG CO2. Source

130*2.38 = 309 Kg CO2

closeEntranze & Environmental Protection Agency

European average = 240 kWh/m² (50% Electricity, 50% Gas) https://entranze.enerdata.net/total-unit-consumption-per-m2-in-non-residential-at-normal-climate.html

120 kWh/m² Electricity = 85 Kg CO2, 120 kWh/m² Gas = 22 Kg CO2 https://www.epa.gov/energy/greenhouse-gas-equivalencies-calculator

Total: 85 Kg CO2 + 22 Kg CO2 = 107 Kg CO2

closeThis is equivalent to greenhouse gas emissions from:

Source: Environmental Protection Agency

FOR 500 M2 THIS reduction WOULD RESULT IN 1,188,500 KG CO2 REDUCTION

A positive contribution to our planet

We apply best practises in energy and water stewardship, combined with great attention to material health. Our commitment is to continue to be the most sustainable producer in our industry, improving the planet and the wellbeing of every individual using our solutions.

We call this: creating space for a healthy planet.

Yearly saving

2,108,000 = 454 **

passenger cars drive for one year

Saving per shelf meter

1.41 kg = 172 **

smartphone charges

Yearly saving

9,652 m3

Yearly saving

25,097 m3

= drinking water for 34,380 people

Saving per shelf meter

16 L

= flushing the toilet 3 times

Yearly saving

15,216 L

Material

What makes us unique in our industry is that we produce with unoiled and non-galvanised steel. By doing this we save*:

- Yearly 2,108,000 kg CO2

- Yearly 25,097 m3 drinking water

- Yearly 96.52 m3 waste

- Yearly 15,216 L chemicals

In additional we are now also able to offer Bruynzeel ‘GreenSteel’ which is steel that is certified and for which the CO2 saving is accounted for by the sum of CO2 savings made throughout the total production of steel by steel producers.

* Based on 2022 production volumes

** Source: Environmental Protection Agency

Steel Comparison

Galvanized

Steel

Steel

Steel containing a layer of zinc to protect against corrosion.

Oiled

Steel *

Steel *

Blank steel which has a layer of oil to protect corrosion during handling and production.

BRUYNZEEL

NON-GALVANIZED

/ UNOILED STEEL *

NON-GALVANIZED

/ UNOILED STEEL *

Blank steel with no oil added during the production.

Bruynzeel

Greensteel

Greensteel

GreenSteel with the lowest available CO2 impact through accredited certificates.

Bruynzeel

Greensteel 2.0

Greensteel 2.0

Fossil-free steel production based on using Hydrogen technology. Expected to be launched in between 2025-2030.

*Always powder coated as surface treatment

Learn more about different steel variations and its environmental impact

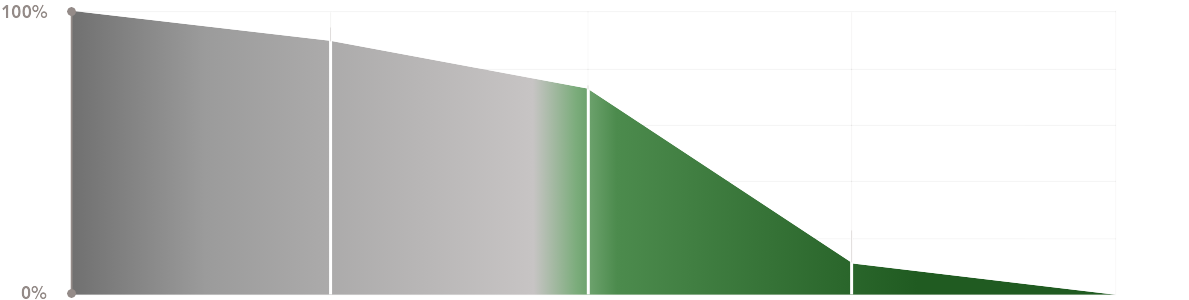

Switching to Bruynzeel GreenSteel can reduce CO2 Impact by >91%!

The majority of the industry still produces with galvanized and/or oiled steel. This used to be Bruynzeel standard as well before 2000. Modernizing our production facilities allowed us to pre-dominantly produce with unoiled non-galvanized steel, which has been Bruynzeel’s standard (>20% less CO2 impact versus Galvanized) for many years now. Now we want to make the next shift towards our new standard → Bruynzeel GreenSteel (>91% less CO2 Impact versus Galvanized!)

Bruynzeel has started to use unoiled steel from 2000 onwards. We shifted from 100% oiled steel then to 80% unoiled and over 95% non-galvanized steel in 2022.

Our goal is to switch to 50% Bruynzeel GreenSteel by 2025 and towards 100% by 2030.

Total KG CO2 impact to process 1KG STEEL:

| Steel type: | |

| Galvanized Steel | 2.93 KG |

| Non-Galvanized Oiled steel | 2.74 KG |

| Bruynzeel Non-Galvanized / unoiled | 2.38 KG |

| Bruynzeel GreenSteel | 0.27 KG |

| Bruynzeel GreenSteel 2.0* | 0.05 KG |

For more detailed source information, please find attached document.

closeCO2 Impact for 1m² mobile storage

> Save 50% m2 space

Industry standard

(Galvanized

Steel)

381 KG CO2

Steel)

Bruynzeel's standard

(BRUYNZEEL

NON-GALVANIZED

/ UNOILED STEEL)

309 KG CO2

NON-GALVANIZED

/ UNOILED STEEL)

Bruynzeel's new standard

(Bruynzeel

Greensteel)

35 KG CO2

Greensteel)

new

source

Mobile storage solution per m² = Average ~130 Kg Steel (Bruynzeel estimate)

For more detailed source information, please find attached document.

close1,000 M2 mobile storage with

Bruynzeel greensteel reduces

346,000 KG CO2

impact versus

industry standard